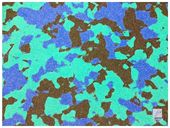

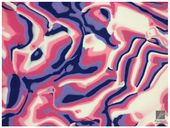

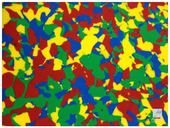

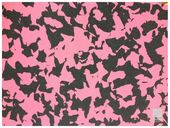

| Material Range Below |

PodiatryInformation for Professionals

Knowing The Orthotic Laboratory

When filling out your prescription form, please ensure that all the shaded areas are completed, to avoid any confusion or delays. When you are sending casts to us please return the original script to us with the casts, and keep the yellow duplicate copy for your records.

You can also complete the digital script, print and send copy with casts if you prefer. Please contact our office and we can forward the digital script to you. Please note that we cannot commence work until both script and cast have been received. We can also receive Scans of the feet and electronic prescription forms. If this is your preferred method, please contact our office to discuss the options available.

Turn-Around On receipt of the casts or scan for prescription devices, we require a Maximum of 7 working days to manufacture your orthotics. The orthotics will be finished and dispatched to you on or before the 7th working day. They will be dispatched by courier FREE DELIVERY ON CUSTOM PRESCRIPTION DEVICES and should be delivered to your nominated address on the following day usually in the morning. To ensure the orthotics are returned to you on your preferred date, you may nominate a date in the “Return Date” section provided on the prescription form. If you have made an appointment for your patient, we recommend that you nominate the return date to be one day prior to the day you dispense the devices. This is to ensure that you do not have any unnecessary delays and that everything runs smoothly for your patients. For CFA (Custom Foot Orthotic / Off the Shelf) devices we require 5 working days from receipt of completed script. Please refer to price list for return delivery costs. Rapid Return We do have an extremely efficient ‘Rapid Return’ system available if you require your fully customized orthotics back within 1-5 working days. However a ‘Rapid Return’ fee will be applied (refer to price list). Adjustments/Recovers Any alterations to orthotics, such as reposting or recovering can be done by completing a prescription form and sending them to us. Please allow 3 working days for these alterations to be returned (refer to price list).Although the vast majority of rework on orthotic devices can be achieved successfully, all recover and adjustment work carries the potential risk of incidental damage occurring to the devices. We exercise all due care and responsibility, however we accept NO responsibility for any incidental damage. We consider all devices over 2 years and non TOL devices to be ‘High Risk” and recommend you discuss these factors with your patients prior to sending work through to us.

Guarantee / Warranty All orthotic shells are covered by a written guarantee against Shell breakage for a period of 12 months, and will upon return of broken devices be remade in accordance with the original script at no charge. Changes to the prescription attract a pro rata extra charge.

Naturally, depending on activity, orthotic covers will deteriorate over a period of time. However, we may replace covers that are abnormally splitting, tearing or lifting (under normal wearing conditions) within the first 30 days of being issued, at our discretion.

Packaging Casts/Transport Once you have named your casts, we recommend that you fill and wrap the casts with newspaper. We would prefer that you do not use the foam beans as they degrade from the moisture in the casts.

Please ensure that all casts have names on them as scripts often become dislodged in the transit process. Place scripts inside each cast or well inside the carton, to stop the scripts being damaged when the box is opened.

If your preferred option is to send Birko (foam) boxes to us, please ensure that they are placed inside a sturdy box to send them to us. The foam boxes themselves are not sturdy enough to stop them being crushed.

Shoe Fit If you foresee shoe fit becoming a problem (or has been a problem), we suggest that you can either send a pair of your patients shoes or an outline of the shoe insole together with the casts or orthotics. Please indicate size and type of shoe on prescription and request “fit to shoes” in special instructions, and we will endeavor to make the suitable adjustments for better shoe fit.

Remakes If you require a remake of orthotics, send us a new prescription form quoting either the orthotic number ( which will be on the label on the underside of the devices) or your original casting date. Even if the second pair of orthotics will be identical to the original a new script marked ‘same as original’ is needed. If there are changes to the original script, we would prefer that you make it extremely clear which details of the original script are to be the same. Any details that require translation often end up confusing the manufacturing process. A 15% discount applies to remakes, unless additional modifications must be made to the casts.

Communication / Correspondence The Orthotic Laboratory strongly encourages communication between practitioners and the Laboratory. To assist us when enquiring about work in progress or previous devices the following information will enable us to answer your queries in the most efficient manner.

We can be contacted either by phone (toll free) on 1800 800 315 Local: 03 9898 8107 or via email address on info@theorthoticlaboratory.com.au

Variations Any variation of our standard orthotic range will be happily accommodated: so please do not hesitate to order your special requirements in the ‘special instructions’ section.

No Cost Option There are a considerable number of no cost options on custom devices, some of which are listed below. 1. Shell flexibility 2. Cambrelle top cover 3. Cambrelle bottom cover 4. Lunasoft top cover 5. Medial / Lateral flanges 6. Aperture heels 7. Plantar fascia grooves 8. Cuboid notches 9. Cast accommodations 10. 1st ray cut-outs 11. Medial flap in cover

When ordering CFA devices please note that they are an off the shelf product that are a more cost efficient option for your patients. There are charges for making modifications to the shells, and you should refer to the price list for the modification and charging options.

Payment Terms An account can be opened after we have received a completed “Application for credit” . For the first few months we prefer upfront credit card payments prior to delivery of orthotics to enable a payment history to be established. Statements are issued at the end of each month, and our payment terms are 30 days from receipt of statement. Payment options are listed on statements for either direct deposit, cheque or credit card payments. Overdue invoices may incur a service fee if paid late by credit card.

Charges The Orthotic Laboratory provides a current price list which applies to our standard Footech range. Custom devices are charged as a base Footech type plus any chargeable additions.

Courier fees for return of custom devices to your address are FREE.

However, orders less than $200 value of CFA/ Prothotics and recover/adjustments will attract a delivery charge. Refer to our price list. Items or service not listed on the current price list will be happily quoted for. Practitioner’s personal devices are free of charge, whilst the immediate family and staff also enjoy a 25% discount off the range of custom orthotics. Please note that the family/staff discounts relate to custom devices only and not the ‘off the shelf’ range.

Please note that all orthotic work is GST free, however GST will apply to freight and other miscellaneous items.

Reserved Rights The Orthotic Laboratory reserves the right to amend its pricing structure, existing policies and manufacturing methods without prior notice. However, we will always endeavor to give prior notice to customers in regard to any major changes whenever possible.

Prescription Form and Terminology

The Orthotic Laboratory prescription has been developed over many years to provide practitioners with a straight forward, flexible and up to date environment with which to prescribe orthotics in. The form is clearly separated into shaded and non-shaded areas. The shaded area is most important and must be completed to ensure a device can be fabricated. The non shaded areas are for modifying the device from its standard construction criteria. The following is an explanation of terminologies and processes, as we interpret them.

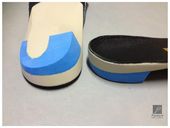

Footech Orthotic Cover Type At The Orthotic Laboratory we have developed a range of standards for devices and applied appropriate names. It should be noted that the type largely refers to the type of cover. Control– shell length cover Control Plus– shell length cover with Soft Tissue Supplement (STS) Web—Sulcus length cover with STS on Web area only Web Plus—Sulcus length cover with STS over shell to Sulcus. Performance– Full length cover with STS over shell and extending to end of toes. Performance Plus– Full length cover with STS over shell and extending to end of toes, with a spenco top cover. Courthotics can be ordered as either a hook style or full heel style. The cover will be a Web cover as a standard.

It should be noted that the standard top cover material is Vinyl on all the range (except Performance Plus), and that the standard STS we use is 1.5 mm Poron or PPT. Material variations can naturally be ordered in the cover options area.

Covers: Additional Information

The covering options section is designed to allow you to modify our standard orthotic type covers, and to meet any specific requirements you may have. Please note some modifications may contradict the basic orthotic type in which case the closest standard orthotic cover type charge will be applied.

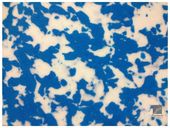

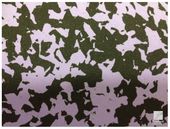

Vinyl Standard Top Covers Dark Grey vinyl is the standard finishing top cover on Control, Control Plus Web, Courthotic and Performance types (a variety of vinyl colours are available on request, please enquire). If you would prefer other top cover materials, please nominate in “covers”, or “Special Instructions”. The top cover may be cut to full shoe length (Performance), Web length (Web) and shell only length (Control).

Cambrelle Bottom Covers To protect the PPT from early breakdown, and to provide extra stiffness to the forefoot cover extension without bulk, we recommend you prescribe a cambrelle bottom cover on Performance, Webs and Courthotics, when required.

Optional Padding PMP’s, shafts, U’D plantar covers and other pads can be made from requested material, however PPT and Eva is more commonly used. If a specific material is not requested for a pad, the standard material used is 3mm PPT.

Neoprene Top Cover Neoprene is a rubatex neoprene rubber impregnated with nitrogen bubbles covered with multi-stretch nylon. It can be useful to reduce friction, absorb shock and reduce blisters and callous. Available in 1.5mm or 3 mm.

P.S. Vlies Also known as HS Cover, is a non woven cotton-polyester polyurethane blend. It absorbs moisture during wear and dries effectively afterwards.

Lunasoft This is an Eva covering material that is flexible, lightweight with good cushioning qualities. It is available in a variety of colours.

Cambrelle Aperture Cover Cambrelle may be a wise choice to cover the apertures as it is effective in protecting the PPT in the heel from premature breakdown.

Shell Material Options Shell material is not intrinsic to our product types. Therefore, you must specify the type of shell material you want. Polypropylene 4.5mm grey is our standard orthotic material and in most cases is considered semi rigid to rigid. 4.0mm white polypropylene is considered semi-flexible. 3.0mm grey polypropylene is considered flexible.

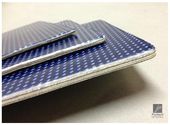

XT Carbon Fibre is a composite material which is thin with high strength and resistant to cracking. It is available in Semi flex 2.3 mm Semi rigid 2.7mm Rigid 3.0mm

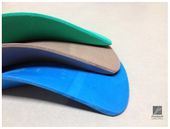

EVA is a light solid material that is generally prescribed as a palliative device, but is also useful when requiring a controlling device at the same time as absorbing forces placed on the foot. It’s various densities are classified by us as follows: Approx 190 kg/m3 is Soft Approx 220 kg/m3 is Medium Approx 400 kg/m3 is Firm

Extrinsic Posts Our standard material is Eva 400(Firm), but can also be applied in medium or soft Eva. Extrinsic posts can be applied as standard stabilizers by marking a basic cross in the rear foot post boxes. If you require extra degrees of correction to be applied extrinsically, please take into consideration the balance of the device and whether it requires a forefoot balancing post.

Heel Lift When a heel lift is applied to an extrinsic post, the height of the lift is measured from inferior surface of the heel seat to the superior surface of the heel cup including the post/lift. The difference between them is the added lift.

Extrinsic Cover Plate Plates are automatically applied to all basic posts. If you don’t require a plate, just cross the No Extrinsic Cover Plate box. However, DC Wedge style devices, posts with apertures, and courthotics DO NOT have plates applied unless advised.

Cast Modifications

Standard/ Modified Root balance

This technique of cast modifications was developed in the 1970’s in response to the perceived limitations of the Root technique in balancing large discrepancies of the forefoot to rearfoot variances; and the desire to increase rearfoot control without creating an aggressive forefoot shelf effect on the anterior border of the device. Podiatrists prescribing this device feel they can intrinsically post greater rearfoot control into the device with increased sustentaculum tali area pressure

Inverted Technique

The Inverted Technique was first documented in the late 1980’s by Richard Blake DPM. It was developed with the desire to achieve greater rearfoot to leg control and increased lower limb transverse plane control. Essentially, it is a technique which produces a varus wedge underneath the rearfoot by canting the foot model via the forefoot post to a much larger degree than can be achieved with a Modified Root or Root balance technique. Dr Blake proposed a 1:5 ratio for correction to control rearfoot motion. i.e. for a NSCP of 5 degrees inverted, the cast would be posted to 25 degrees inverted. We recommend a more conservative approach to correction with your initial inverted prescriptions: i.e. 15 to 25 degree maximum. Some indications for use of an Inverted Device: Medial knee pain, Achilles tendonitis, posterior tibial tendonitis or posterior tibial insufficiency syndrome, sinus tarsi syndrome, pes. planus. Some contra-indications possible with an Inverted Device: chronic inversion ankle sprain, severe ankle equines, severe genu varum, forefoot valgus and plantar flexed 1st ray when lateral instability is present. Symptoms related to contact phase lateral instability due to : peroneal tendonitis, fibular stress, medial menisial symptoms, long periods of static weight bearing.

DC Wedge

This is an inverted style device which was developed by The Orthotic Laboratory in early 1991 and is now extensively used by many of our clients. It is a method that is designed to reduce a weight bearing hyper-pronated foot, and its design criteria was to create an inverted style of orthotic that would provide:

It differs from the Blake inverted and also the Medial heel skive technique. The DC Wedge modifications are applied to the lateral plantar aspect of the heel, with the contact point beginning at the tangential point to the cast. No corrective forefoot post is used, but one is applied to define length only. A cuboid notch is applied to assist in positioning the rear foot and to prevent medial slippage. Heel stabilizers are highly recommended for all DC Wedges and are automatically applied at the Lab. Kirby Skive

This technique involves removing small amounts of the medial portion of the plantar heel of the foot model to create a varus wedging effect within the heel cup. The skive effect is placed at a 12- 15 degree angle with the nominated depth in mm’s. In Recent years we tend to request practitioners order in small, medium or large (S,M,L) as the depth method often results in irregular results due to variables in heel shape, morphology and size. Where Small is apx. 10-15mm diameter, medium is apx. 15-30mm diameter and large is apx. 30-40+mm diameter. Corrected Calcaneal Bisection Position This refers to the postion of the calcaneal bisection of the cast, when intrinsic posting and balancing is completed. All corrected positions should be indicated in degrees of eversion or inversion from the vertical position. This is one of the most important sections on the form as it is the basis of the laboratory’s modification stage. The intrinsic forefoot post (unless otherwise indicated) will be balanced plantar-grade to the rearfoot. Minimal Medial Arch Expansion Where a variation from the accepted standards for medial arch expansion in any of the cast modification styles is required, indication of minimal medial arch expansion will instruct the laboratory to add a minimum of expansion to the arch. This will result in a device having a higher medial arch. Extra Medial Arch Expansion An indication placed next to this will result in more expansion added to the mould, which will result in the shell being lower in the arch. Lateral Cast Grind A lateral cast grind is applied to the lateral side of the cast, generally under the 5th ray by the amount of mm’s requested. This will result in an orthotic shell with a higher lateral side. Cuboid Notch A cuboid notch will apply a pronatory force across the midtarsal joint, assists in positioning the rearfoot and can help prevent lateral slippage. The depth on the notch is usually 4,6 or 8mm, and should be provided on the script. Accommodate Cuboid For a patient with a flexible high lateral arch you may anticipate irritation. If so, extra fill in the cuboid area of specified thickness may be considered which results in a depression in the shell. Accommodate Styloid A prominent 5th metatarsal styloid process in either a lateral or plantar direction may in severe cases be irritated by an appliance. When sensitivity is apparent in this area, mild expansion can be added to create a depression or “accommodation” in the finished device. Add Lateral Heel Expansion A heel with excessive soft tissue displacement when weight bearing, may be irritated by the lateral aspect of the orthotic heel cup. By prescribing in mm additional lateral heel expansion will be added to the lateral heel area of the cast. The result in the finished device will be a widening of the lateral heel cup to accommodate for this displacement. Inverted devices of greater than 20 degrees may also require additional lateral heel expansion to minimize the potential for heel cup pinching to occur. Please Note: additional heel expansion will widen the heel cup and can make shoe fit more difficult particularly when higher (above 12mm) heel cups are ordered.

Accommodate as Indicated on Cast Any lesion or prominence that is a potential point of irritation can be accommodated for in the device by adding to that area of the cast to create a depression in the shell, therefore potentially relieving pressure to that point. They should be clearly marked on the cast or foot when scanning by the podiatrist.

Other Shell Options

Pod. Specified Shell In this grid , you are able to give us specific measurements for the shell that you require. Length of shell is measured from a position approx. 20mm up the centre posterior heel to approx. the 3rd met head bisection. Heel width is measured at the widest part of the heel at the position 20mm up the sides of the heel. Forefoot width is the width requested for the shell anterior edge width. Arch height is the approx. highest point required in mm Please note that there is a tolerance of approx. 2mm in all the measurements.

Apertured Heel This is a technique used to reduce the bulk of the device from the plantar aspect rather than the superior aspect of the heel cup. It can also be useful when palliation of lesions and spurs is required as the aperture can be filled with Poron / PPT in standard form or with cambrelle as an option. When an aperture is requested it will be applied to the contact surface area of the shell to enable better shoe fit. Alternatively, if an aperture is required elsewhere on the shell please mark area on the cast and/or diagram. scanning customers please mark on foot before scanning.

First Ray Cut-out A plantar flexed first ray can be accommodated by a first ray cut-out, thereby allowing it to plantarflex. Simply it is the removal of the medial anterior corner of the shell.

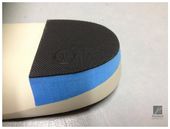

Low Bulk Grind Primarily designed to improve shoe fit in narrow or low cut shoe types. The low bulk grind is simply a grind around the medial, lateral and heel edges of the shell at usually greater than 45 degrees to the perpendicular with the inferior surface. It is often prescribed in conjunction with lateral plantar grind and medial curve grind to significantly reduce bulk for difficult to fit shoe types.

Lateral Plantar Grind The lateral plantar grind is a grind to the lateral plantar surface of the device. The primary use is to assist in accommodating the device in footwear by reducing lateral plantar material thickness, thereby following the contour of the shank of the shoe. It is most often prescribed for ladies, men’s fashion shoes, feet with a flat lateral arch and to reduce the possibility of the orthotic rocking in shoes with contoured shanks.

Medial Curve Grind On occasions the medial orthotic edge may exert pressure on the medial aspect of the shoe upper, leading to an impression being made into this part of the shoe. In some cases the device may also cause a widening of the medial shoe upper resulting in foot slippage. These effects may occur particularly when the orthotic has been requested to be trimmed wider than the first MTP joint bisection or is intended wear in narrow shoe types, An orthotic that reduces the width in the middle of the device but not reducing width at the anterior edge can be prescribed. This is referred to as a medial curve grind. This may also be a useful modification when prescribing for a metatarsus adductus foot

Plantar Fascia Accommodation or Groove A prominent plantar fascia can be irritated by wearing orthoses. This can be accommodated in the orthotic by either an addition on the cast (accommodation) or by grinding a groove in the orthotic (groove). To determine the amount of accommodation required, place a ruler on the plantar aspect of the foot, immediately adjacent to the plantar fascia.

With the foot non-weight bearing and relaxed, dorsiflex the ankle and the first MTP joint, and measure the prominence of the plantar-fascia, and record on the prescription form in mm. The result in the shell is to create a lineal depression along the plantar fascial position. It is recommended that the plantar fascial position is marked on the negative cast to assist with accurate positioning. In general a groove is recommended for polypropylene shells and an accommodation in XT Carbon Fibre.

Heel Cup Height This is measured from the posterior aspect of the heel cup, in a line from the inferior surface of the heel seat to the superior surface of the heel cup. It includes the material thickness of the heel seat which unless apertured, is usually ground to 1mm thickness. This also includes the extrinsic heel cover plate thickness when extrinsic posts and cover plate are prescribed. Standard heel cup height is12-15mm.

Medial Flange If you require the medial aspect of the heel cup to be higher than the measured posterior aspect of the heel cup, then a medial flange can be prescribed. It is measured from a centre point on the medial aspect of the heel cup in a line from the inferior surface of the heel seat to the superior surface of the heel cup.

Lateral Flange If you require the lateral aspect of the heel cup to be higher than the measured posterior aspect of the heel cup, than a lateral flange can be prescribed.It is measured from a centre point on the lateral aspect of the heel cup in a line from the inferior surface of the heel seat to the superior surface of the heel cup.

Gait Plate (request in Special Instructions) Gait Plates can be requested in the Special Instructions. Patients who present with an in-toeing gait may benefit from an orthotic with a lateral gait plate. The anterior edge of the shell is ground from behind the 1st met head to the end of the fifth toe. It is constructed conversely for an out-toeing patient. However, the only information we require is the orthotic shell requirement, not the patient’s gait. We recommend that you draw on the foot diagram the shell shape, just to confirm.

To ensure simplicity, the form is shaded into two distinct areas; the shaded top half and the non-shaded area underneath.

The shaded area is vital and must be completed FULLY for The Orthotic Laboratory to commence making the orthoses. The Laboratory will assume a standard device is required when this is the only area filled out.

IMPORTANT

Where any individual or all shaded subsections are not filled out the following standards will apply in any missing section:

The non-shaded area contains a variety of additions and options which can be indicated when variation from the standard T.O.L. standard is required. No assumptions will be made by the Laboratory in this area, and relevant additions and options will only be acted upon when indicated.

This grid is an optional area if you would prefer to supply us with specific orthotic shell measurements. There are four measurements within the grid, and we suggest the measurements to be supplied in the following manner: Length of shell should be measured from the point at the center / posterior of the heel at a height of approx 20mm from the ground towards the 3rd bisection of the met head. Heel width should be measured at the widest point of the heel, at a height of approx 20mm from the ground. Forefoot is the width measurement of the anterior edge of the shell at widest point. Arch height is the highest point required. Please note that a tolerance of approx 2mm applies.

We have developed over the years a range of standards for devices and applied appropriate names, and these refer largely to the type of cover as follows: Control– shell length cover, vinyl is standard Control Plus—shell length cover with Soft Tissue Supplement (STS) Web– Sulcus length cover with STS on Web area only Performance—Full length cover with STS over shell extending to toes. Vinyl top is standard Performance Plus– Full length cover with STS over shell extending to toes, with a top cover of Neoprene Courthotic– A hook or full heel style can be ordered, the default style is hook if nothing is specified

It should be noted that the standard top covering material is Vinyl , and the STS is 1.5mm PPT or Poron. Material variations can be ordered in the Cover Options area, extra cost may apply.

|